Baker ZTX Low-Impedance Coil Test Accessory

Extend the functionality of Baker DX and Baker AWA-IV analyzers to tests of low-impedance DC windings or coils

Low-impedance coils typical of DC armatures, coils or interpoles can make it difficult to detect insulation weaknesses. The low inductance characteristics of armature windings require high test currents to achieve the minimum voltage levels needed to accurately detect insulation weaknesses. The Baker ZTX provides the necessary current at low test voltages to find insulation problems when using Baker static motor analyzers. Compatible with 6 kV, 12 kV and some 15 kV models in the Baker DX and Baker AWA-IV static analyzer families, the ZTX extends the types of coils that can be tested.

When coupled with the appropriate 6- or 12-kV Baker static motor analyzer, the Baker ZTX allows motor manufacturing and repair shop personnel to perform a comprehensive array of tests on the coils of a DC armature. The ZTX applies a surge pulse to two adjacent bars on the armature to produce a reference waveform, which is saved on the host analyzer. Successive bars are then tested with automatic comparisons to the reference waveform. A bar graph of error-area ratio (EAR) values can be created for easy comparison and analysis. The precise mathematical analysis of the EAR algorithm minimizes the inaccurate analysis that often occurs with mere visual comparisons of the waveforms.

Improve service QC

With any inspection of a used armature, or when quality control efforts are performed on new or rebuilt armatures, turn-to-turn insulation needs to be free of any scratches, pinholes or damage of any kind. The Baker ZTX reduces the possibility of overlooking such damage before the motor is cleared for service use.

Safety and convenience

The Baker ZTX includes the ATF5000, a hand-held safetygrounded armature contact device to make it as easy and safe as possible to perform resistance and surge tests on

DC commutators. This device measures the surge voltage wave at the commutator via a separate shielded cable, which reduces errors in the test voltage readings. The test waveform is displayed on the host analyzer (i.e. a Baker DX or Baker AWA-IV). The ATF5000’s Kelvin probes allow accurate resistance testing. Additional low voltage tests

include inductance, impedance and phase angle. The accessory also comes with a foot-switch, which improves speed and efficiency for repetitive tests on armatures.

Bar-to-bar vs. span tests

Manufacturers and rebuilders of industrial DC motors prefer the use of bar-to-bar tests over span tests to improve quality control. The bar-to-bar test method is more comprehensive than span or other DC motor insulation test techniques. The span test method enables comparisons of spans across several rotor bars, but is limited at low

currents. The Baker bar-to-bar method enables tests of turn-to-turn insulation at lower voltages, but at a current high enough to simulate what a motor experiences in actual service.

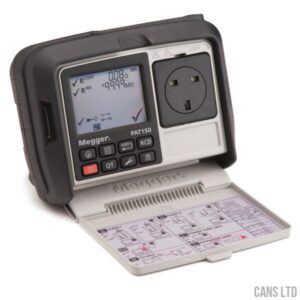

megger-awa-IV

megger-awa-IV