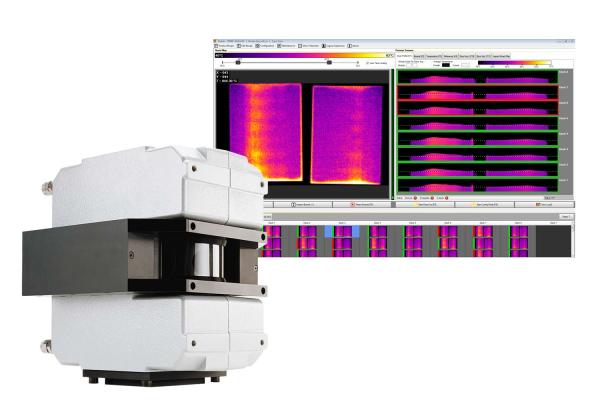

TIP900 Thermal Imaging System

The complete, intelligent and easy-to-use solution … saving you time and money

The TIP900 system is a comprehensive thermal imaging and noncontact profiling solution designed to supervise the temperature of wallboards coming out of the oven. It uses

an infrared thermal imager to continuously scan the entire board surface temperatures and allows the detection in real time of moisture and density variations inside each board.

The software is designed to monitor and adjust for maximum board quality and detect defects or process changes. It also analyzes and provides optimal oven dryer profile balance. The detailed board quality maps, the historical board temperature trend charts and the images can be seen locally at the operator workstation or remotely. All data is stored in the LogViewer database for complete process visibility and long term traceability.

Intelligent Software Package

The powerful TIP900 software provides sophisticated data integration, visualization and event analysis, and offers users a complete solution of real-time monitoring, detection and traceability.

- Detailed continuous board quality monitoring (100% of all board images are archived)

- Easy recipe setup – automated scaling

- Automated board defect detection and rejection

- Ethernet connectivity: process data, defect reports, dryer balance profile, etc., can be shared with HMI

- Dynamic deck-to-deck dryer profile balance monitoring

- Failure identification function tracked in database

- Database LogViewer for historical analysis (for remote access viewing of any TIP900 on a company network)

- Configurable reject/alarm parameters

Applications

The TIP900 system performs real-time board temperature monitoring, defect detection & rejection, and dryer balance imaging. The thermal imager scans the entire board

surface temperatures with more than 40,000 data points each second. This high level of resolution allows the system to automatically detect the most minor board quality issues.

Failure Detection

- Over/under-dried boards

- Paper blisters

- Edge peel/end burns

- Paper blows

- Mixer voids & clumps

- Belt splices

- Overlapped boards

- Cracks and bubbles

The Fluke Process Instruments Guarantee

The TIP900 system is supported by a 2 year warranty. With a network of trained representatives and agents in over one hundred (100) countries and offices located in the U.S., Germany and China, we provide local service and support you can rely on time after time.

Benefits

Complete – system includes hardware, software and industrial housings for operator-friendly use in industrial environments

Intelligent – provides detailed continuous board quality monitoring and automatic defect detection

Cost saver – quick return on investment and higher worker efficiency

TIP900-thermal-imaging-system

TIP900-thermal-imaging-system