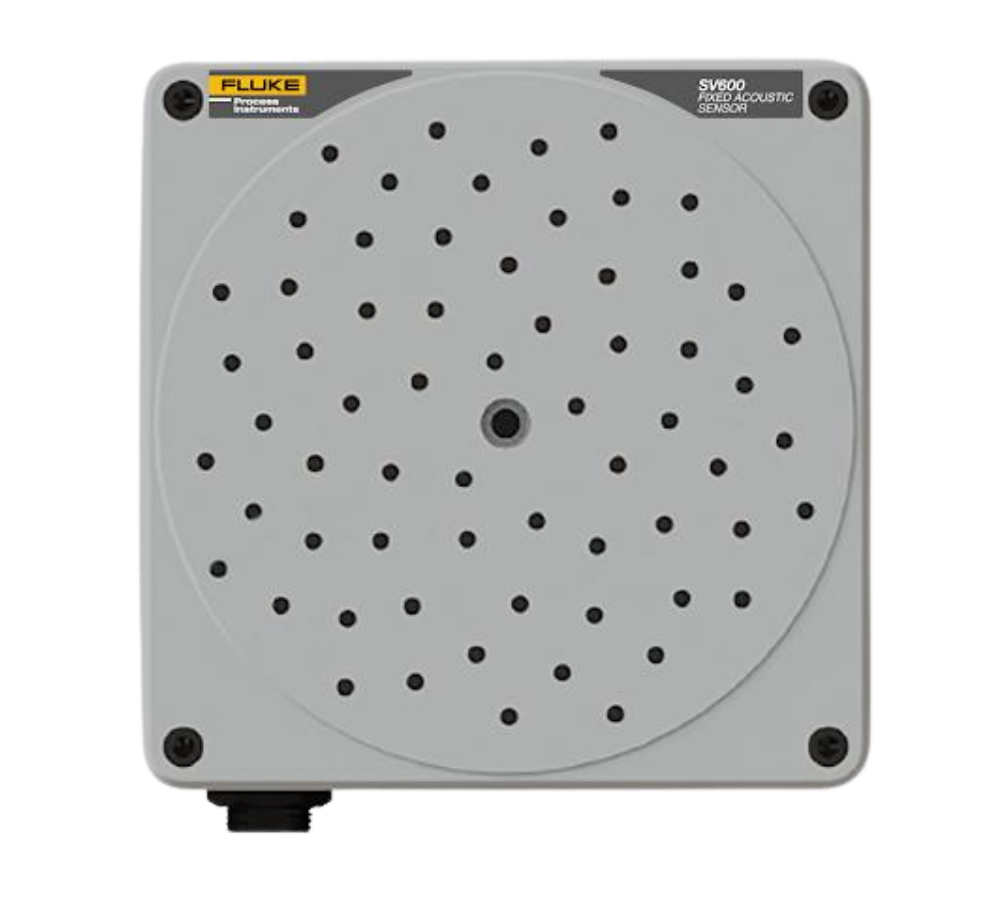

SV600 Acoustic Imager

Process and Asset Monitoring

Detect, locate and visualize sound signature changes across your process and equipment:

• Monitor equipment changes in real-time – The SV600 continuously monitors your process for air and gas leaks, steam or vibrations and visually records any anomalies alerting users to areas of concern immediately.

• Prevent unscheduled maintenance – Sound signatures are measurable well before any change in temperature can be detected. The SV600 can be used to find sound signature changes early on so facilities can schedule preventative maintenance and optimize performance before a failure occurs.

• Capture data from inaccessible locations – The SV600 can be mounted close to any equipment or asset, to any area of the production line or where human access is restricted or dangerous.

• Continuous learning/improvement – The SV600 can identify sound events, both relevant and irrelevant, and using a sophisticated algorithm, filters out bad sound events over time – improving users’ overall detection rates.

• Reduce power consumption – By quickly detecting and fixing air leaks, you can reduce your consumption of compressed air and energy to help save your facility money. Faulty, inefficient drive systems need to work harder, consuming additional power to stay operational.

On-Site Safety

Improve safety by continuously monitoring assets located in inaccessible areas, detecting new sound events in a critical factory location, or finding and visualizing escaping gases from fixed equipment.

- Minimize human intervention – Improve workers’ safety overall with a fully integrated, automated solution.

- Monitor assets and workspaces 24/7 – Continuously monitor assets in hazardous or inaccessible locations at a safe distance, receive immediate alarms for new sound events or detect escaping gases from fixed equipment.\

- Reduce noise exposure – The SV600 includes user-programmable alarms for sound level (dB) and frequency (kHz) to help facilities better meet national and international standards and ensure workers are not exposed to dangerous noise and sound levels

Inspections

Detect, locate and visualize sound signature changes across productinspection and quality control processes:

• Intelligent leak detection – Using factory integration and real-time alarm features, the SV600 can automate acoustic detection on the production line and immediately notify your team of any quality issues or product rejects, improving productivity.

• Minimize operator intervention – As a fixed, automated solution that integrates with your process, the SV600 eliminates the need for the constant operator intervention required of handheld sniffers, soap and water tests, manual audible methods or portable acoustic devices.

• Capture data from inaccessible locations – The SV600 can be mounted close to any equipment or asset, to any area of the production line or where human access is restricted or dangerous.

• Automate product inspections – The SV600 can be fully integrated with the factory system, supporting improved automation and efficiency and allowing users to automate their product inspections. With a fully digitized process, data can be recorded and archived to enable improved product traceability.

Spot What You’ve Been Missing

The SV600 can also be used as a payload for Boston Dynamics’ agile mobile robot Spot®.

Spot takes inspection to the next level. Designed to go where other robots can’t go and to perform a broad number of tasks, Spot traverses unstructured terrain to automate industrial inspections, monitor remote or hazardous environments and provide situational awareness in remote settings.

The robot can also be reconfigured for various use cases to increase efficiency and greatly reduce safety risks. With the SV600 payload Spot will now be able to automate air and gas leak detection and identify sound signatures, all while on the go.

Model Overview

SV600-1

Standard Model plus VIS camera

SV600-BD

Payload for Boston Dynamics Spot® Robot

Includes:

• SV600-1 Sonic Viewer

• Protective Metal Frame to mount on Spot

• Connection Cable to Spot

fluke-SV600-datasheet

fluke-SV600-datasheet