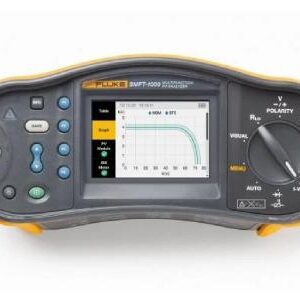

Fluke MDA-550 Series III Motor Drive Analyzer

The MDA-550 is the ideal portable motor-drive analysis test tool, and can help safely locate and troubleshoot typical problems on

inverter type motor-drive systems.

• Measure key motor-drive parameters including voltage, current, DC Bus voltage level and AC ripple, voltage and current unbalance and harmonics, voltage modulation, and motor shaft voltage discharges.

• Perform extended harmonics measurements to identify the effects of low and high order harmonics on your electrical power system.

• Conduct guided measurements for motor-drive input, DC bus, drive output, motor input and shaft measurements with graphical step-by-step voltage and current connection diagrams.

• Use simplified measurement setup with preset measurement profiles to automatically trigger data collection based on the chosen test procedure.

• Create reports quickly and easily that are perfect for documenting troubleshooting and collaborative work with others.

• Measure additional electrical parameters with full 500 MHz oscilloscope, meter and recording capability for complete range of electrical and electronic measurement on industrial systems.

The Fluke MDA-550 Motor Drive Analyzer uses guided test measurements to make analysis easier than ever

Drive input

Measure input voltage and current to quickly see whether values are within acceptable limits by comparing the drive’s nominal

rated voltage to the actual supplied voltage. Then, check the input current to determine if the current is within the maximum rating

and the conductors are suitably sized. You can also check whether the harmonic distortion is within an acceptable level by visually

inspecting the waveform shape or by viewing the harmonics spectrum screen which shows both the total harmonic distortion and

individual harmonics.

Voltage and current unbalance

Check the voltage unbalance at the input terminals so you can ensure the phase unbalance is not too high (> 6-8 %), and that the

phase rotation is correct. You can also check the current unbalance, as excessive unbalance may indicate a drive rectifier problem.

Extended harmonic measurements

Excessive harmonics are not just a threat to your rotating machines but also to other equipment connected to the electrical power

system. The MDA-550 provides the ability to discover the harmonics of the motor-drive but can also discover the possible effects of

inverter switching electronics. The MDA-550 has three harmonic ranges, 1st to 51st Harmonics, 1 to 9 kHz and 9 kHz to 150 kHz

giving the ability to detect any harmonic pollution problems.

DC bus

In a motor-drive the conversion of AC to DC inside the drive is critical, having the correct voltage and adequate smoothing with low

ripple is required for the best drive performance. High ripple voltage may be an indicator of failed capacitors or incorrect sizing of

the connected motor. The record function can be used to check DC bus performance dynamically in the operating mode while a load

is applied.

Drive output

Check the output of the drive focusing both on voltage to frequency ratio (V/F), and voltage modulation. When high V/F ratio measurements are experienced, the motor may overheat. With low V/F ratios, the connected motor may not be able to provide the required torque at the load to sufficiently run the intended process.

Voltage modulation

Measurements of the Pulse Width Modulated signal are used to check for high voltage peaks which can damage motor winding

insulation. The rise time or steepness of impulses is indicated by the dV/dt reading (rate of voltage change over time), this should

be compared to the motor’s specified insulation. The measurements can also be used to measure switching frequency to identify

whether there is a potential issue with electronic switching, or with grounding, where the signal floats up and down.

Motor input

Ensuring that voltage is being supplied at the motor input terminals is key, and the selection of cabling from drive to the motor

is critical. Incorrect cabling selection can result in both drive and motor damage due to excessive reflected voltage peaks. Checking

that the current present at the terminals is within the motor rating is important as over current condition could cause the motor to run

hot, decreasing the life of the stator insulation which can result in the early failure of the motor.

Motor shaft voltage

Voltage pulses from a variable speed drive can couple from a motor’s stator to its rotor, causing a voltage to appear on the rotor

shaft. When this rotor shaft voltage exceeds the insulating capacity of the bearing grease, flashover currents (sparking) can occur,

causing pitting and fluting of the motor bearing race, damage that can cause a motor to fail prematurely. The MDA-550 is supplied

with carbon fiber brush probe tips that can easily detect the presence of destructive flashover currents, while the impulse amplitude

and count of events will enable you to take action before failure occurs. The addition of this accessory allows you to discover potential damage without investing in expensive permanently installed solutions.

Step-by-step guided measurements ensure you have the data you need, when you need it

The MDA-550 is engineered to help you quickly and easily test and troubleshoot typical problems on three-phase and single-phase

inverter type motor-drive systems. The on-screen information, and step-by-step setup guidance make it easy to configure the analyzer

and get the drive measurements you need to make better maintenance decisions, fast. From power input to the installed motor,

the MDA-550 provides the measurement capability for the fastest motor-drive troubleshooting

fluke-MDA-550-series-datasheet

fluke-MDA-550-series-datasheet